Add to Cart

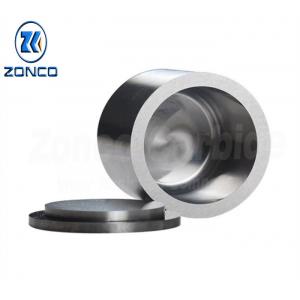

500ml Highly Polished Tungsten Carbide Grinding Jar with Lid

Grinding jars

The selection of the right grinding jar and the correct filling level has a big impact on the grinding result. According to the application you have to select the correct material and amount/volume for the grinding jar and the grinding balls.

A jar filling should consist of about 1/3 sample and 1/3 ball charge. The remaining third is the free jar volume that is necessary for the movement of the balls. The following table provides recommendations.

Selection guide for grinding jars and balls

We recommend to select always grinding jars and balls built from the same material

Recommended ball charge

| Nominal Volume | Sample Amount | Max.feed size | 5mm | 10mm | 15mm | 20mm | 30mm | 40mm |

| 125ml | 15-50ml | <4mm | 500pcs. | 30pcs. | 18pcs. | 7pcs. | ||

| 250ml | 25-120ml | <6mm | 1200pcs. | 50pcs. | 45pcs. | 15pcs. | 6pcs. | |

| 500ml | 75-220ml | <10mm | 2000pcs. | 100pcs. | 70pcs. | 25pcs | 8pcs. | 4pcs. |

Planetary Ball Mill Applications

| Technical Data | |

| Electrical requirements | 200-240 volt 50/60 Hz |

| Motor power | 1500 Watt |

| Transport data | |

| Dimenstions closed WxDxH | ca.759×645×550mm |

| Weight | 158 Kg(only machine) |

| Features/Performance | |

| Working principle | impact,friction |

| Feed size maximum | <10mm |

| Number of grinding jars | 4/2 |

| Max.volume of each grinding jar | 250 ml |

| Min volume of each grinding jar | 10 ml |

| Max.endfineness | <1;<0.1 for collodal grinding |

| Adjustment of grinding duration | digit.adjustable |

| Start/stop function | 1 |

| Setting of grinding time | digital,00:00 ti 99:59 |

| Interval operation | yes,with direction reversal |

| Pause time | 00:00 to 99:59 |

| Speed ratio | 1:-2; 1:-2.5: 1:-3 |

| Sun wheel speed | 50-400min |

| Effective sun wheel diameter | 360mm |

Products show

Common alloy grates,ghysical mechanical properties and recommended application

| Common Alloy Grades, Ghysical Mechanical Properties And Recommended Application | |||||||

| Grade | WC% | Co/Ni % | Physical and mechanical properties | Grain size (μm) | Recommended application | ||

| Density (g/cm3) | TRS (N/mm2) | Hardness (HRA) | |||||

| ZG01 | 100 | 0 | 15.3-15.5 | 1200 | 95.5 | 0.3 | Ultra-high hardness, high wear resistance, anti-corrosion, with certain anti-destructive ability |

| ZG04X | 96 | 4 | 15.0-15.2 | 1600 | 92.8 | 0.8-1.0 | Suitable for drawing die, non-ferrous metal wire drawing and wear-resistant parts |

| ZG06 | 94 | 6 | 14.8-15.1 | 2500 | 90.0 | 1.2 | Good abrasion resistance, good compression resistance, suitable for wear-resistant parts that resist abrasion and high pressure. |

| ZG06X | 94 | 6 | 14.8-15.1 | 2400 | 91.5 | 1.0 | Superio wear resistance,good comprehensive properties,suitable for making non-standard structure components with higher wear resistance. |

| ZG06A | 94 | 6 | 14.8-15.1 | 2150 | 92.5 | 0.6-0.8 | |

| ZG08 | 92 | 8 | 14.6-14.9 | 2700 | 89.0 | 1.2-1.6 | Good general performance, used for general wear parts, molds, general tools, etc. |

| ZG10.2 | 90 | 10 | 14.3-14.6 | 3800 | 91.7 | 0.7 | Good general performance, suitable for casing and oil nozzle products |

| ZG11 | 89 | 11 | 14.3-14.7 | 2800 | 88.5 | 1.2-1.6 | Anti-wear, anti-erosion, good comprehensive mechanical strength, suitable for wear-resistant parts in the petroleum, chemical and mechanical industries. |

| ZG12X | 88 | 12 | 14.2-14.5 | 3000 | 89.5 | 1.0-1.2 | Anti-erosion, good comprehensive mechanical strength, suitable for impact-resistant wear-resistant parts, molds, and roller rings. |

| ZG15 | 85 | 15 | 13.8-14.2 | 3000 | 86.5 | 1.2-1.6 | |

| ZG15X | 85 | 15 | 13.8-14.2 | 4500 | 89.0 | 0.7 | Excellent wear resistance and toughness,it is suitable for making integral stamping dies, anti-vibration toolholders, etc. |

| ZG20 | 80 | 20 | 13.4-13.8 | 3100 | 85.0 | 1.0 | Excellent wear resistance and toughness |

| ZN06 | 94 | 6 | 14.5-14.9 | 2000 | 90.0 | 1.2 | Non-magnetic alloy, suitable for sealing ring, non-magnetic wear-resistant parts and corrosion-resistant parts. |

| ZN09 | 91 | 9 | 14.3-14.6 | 2300 | 89.0 | 1.2-1.6 | |

| ZN11 | 89 | 11 | 14.0-14.3 | 2600 | 88.0 | 1.2 | |